Our advanced revegetation program, BioGrowth™, paired with its associated products and technologies, are manufactured by EnviroStraw here in Australia.

This pioneering program has been successfully implemented in expansive projects such as the Pacific Complete Highway (Woolgoolga to Ballina), and by Glencore Mining, BHP, White Haven Coal, and on the BinnaBurra Fire rehab works. As a vanguard in the field, EnviroStraw takes pride in specialising in establishing vegetation on highly disturbed soils commonly found on construction and mining sites, thereby facilitating carbon sequestration and offering potential avenues for carbon offsetting.

We have developed tried and proven revegetation programs that are both easy to implement and cost-effective. These solutions have consistently delivered the desired outcomes for our clients, both here in Australia and internationally, enhancing carbon sequestration opportunities through vegetation growth and sub-surface next-generation microbiology.

Features & Benefits

The BioGrowth™ Re-Generative Re-Vegetation Program embodies a new paradigm in environmental restoration, designed to be easy to implement while reducing overall project costs. It fosters the development of an optimum rhizosphere for plant growth, using nature’s components and emphasizing on carbon sequestration and the carbon sponge (improving water use efficiency and soil stability – critical in erosion control) – thereby facilitating potential carbon offset opportunities.

It stands superior to other conventional programs because all components needed to create functionally sustainable soils are present in a single bale of EnviroMatrix ECM Biotic Growth Amendment and BFM Complete. Its performance, especially in carbon building, supersedes typical compost/topsoil lime and gypsum installations, as it does not require the traditional volume-based application of these products. Application rates are carefully determined to foster optimal microbial and mycorrhizae growth, alongside ideal carbon components, to rejuvenate the natural biology of disturbed soil on construction sites, playing a vital role in carbon sequestration and the global efforts towards carbon neutrality.

The BioGrowth™ innovative approach yields savings in time and money, manifested in the following ways:

- Water Requirements Reduction: Drastically reduces water consumption by many thousand litres on any project. This is due to the higher mix ratios of the hydromulch medium, which allows for an extended coverage area per tank of Hydromulch applied. This translates to an average saving of 300,000 litres for every 10 hectares treated.

- Soil Conditioning and Amelioration Practices: These practices are significantly reduced, as the requirement for materials like Lime, Gypsum, and compost are markedly reduced, translating into savings on delivery charges, purchase, and application costs.

- Reduced on site Traffic Management Requirement: significantly alleviates the necessity for extensive traffic management and the use of hard stand areas at project sites, primarily due to the reduced volume of soil conditioning materials required to be transported and delivered onsite. This in turn minimizes vehicle movements including water carts, loaders, tractor spreaders, and other associated vehicular activities, which considerably cuts down on diesel fuel consumption and emissions.

- Carbon Emissions Reduction: Consequently, this reduced need for traffic leads to a substantial reduction in the project’s carbon emissions, fostering a lower carbon footprint and facilitating opportunities for carbon offsetting. The streamlined approach not only contributes to the global effort towards carbon neutrality but also enhances the efficiency and environmental sustainability of the entire project.

- Application Costs: Application costs are substantially reduced as ameliorates are applied via the hydromulch equipment, enabling an expansive coverage of 6-8 hectares of area per day, speeding up project completion timelines. This is in comparison to conventional agricultural spreading programs which require increased mobilisation of machinery, tractors, loaders, and spreaders to the project site, which can also lead to extending the project completion time frame.

- Sustainability: Our next-generation beneficial soil Microbe technology are specialists in carbon sequestration, soil stabilisation and increased soil health and plant resilience. Our array of Hydromulch products is manufactured from waste and recycled materials, promoting a circular economy. It helps in preventing soil loss, a prominent global biodiversity issue, while protecting our waterways and environments from nutrient leaching and volatilization.

Cereal straw is sourced from stubble often burned in the farmers paddocks, recycled paper from the recycling industry. Topsoil and or compost as a soil conditioner is not required when a suitable subsoil is available. Compost can be considered sustainable; however, great care needs to be taken in its production to prevent the spread of weed species and excess soluble nutrient. We use microbially-mediated controlled release fertiliser (CRF) manufactured from non-leaching waste ores from the mining and quarrying industries. Water-soluble fertiliser is not part of our program, protecting our delicate waterways and eco sensitive environments from nutrient leaching and volatisation.

- Post Application Water Savings: Options that require no watering, providing up to 12 months of functional longevity of the Hydromulch layer, protecting seed and soil surface, and saving up to 42000 liters of water per hectare during the application process are available.

- Native Plant-Ready: The BioGrowth™ program is adept at establishing native vegetation, often achieving this feat in under six months, given favourable climatic conditions.

- Australian Made: Proudly manufactured in rural Australia utilizing Australian renewable resources, thereby supporting farmers and rural Australia.

- Mix More Spray More: By mixing higher rates of hydromulch in each tank, thereby greatly enhancing site efficiencies as more area can be covered daily.

- Independently Tested: Rigorous independent laboratory and university testing ensures the program and products adhere to world standards and deliver the desired outcomes, having won international awards.

- Full Range of Products: Including Std Hydromulch, Bonded Fibre Matrix (BFM), Biotic Growth Amendments, soil stabilizing polymers, and specially designed soil amendments.

- Economic Advantage: Offers substantial economic benefits compared to other similar programs available in Australia and globally.

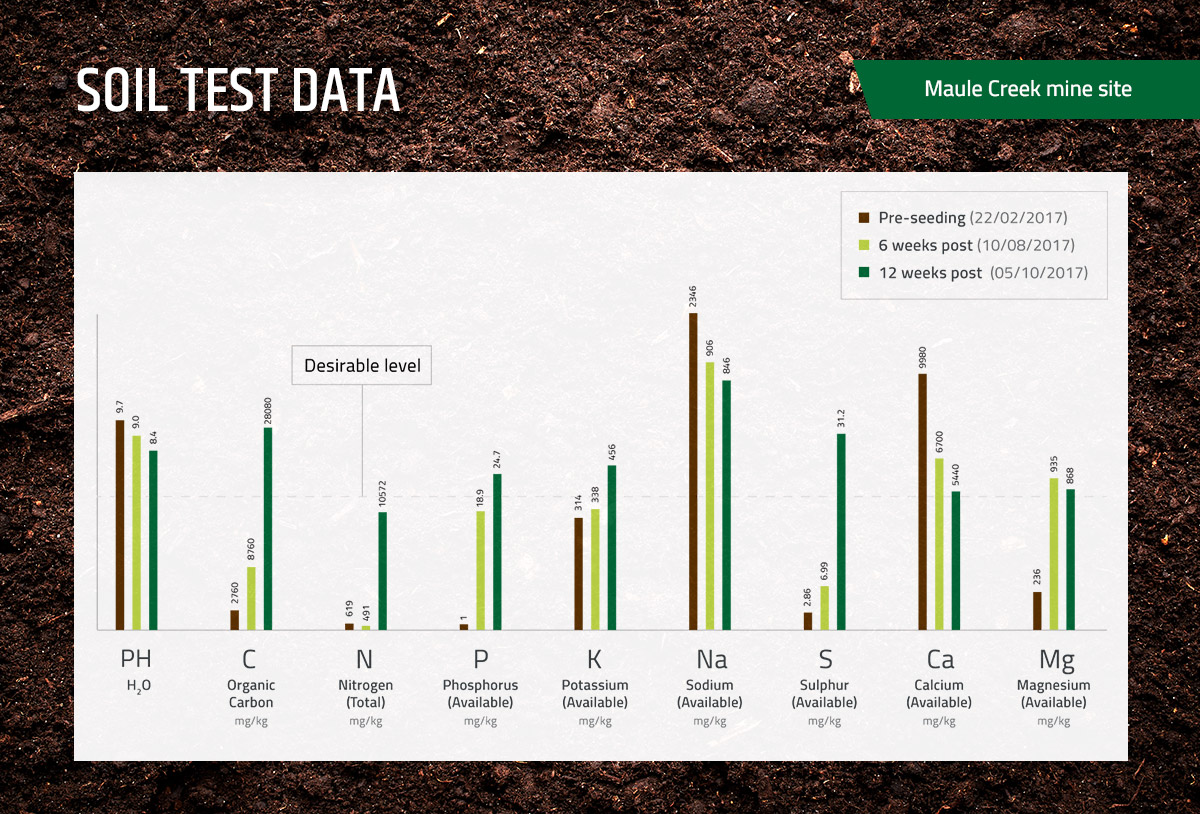

This remarkable program has proven its prowess in balancing and remedying challenging soils, as demonstrated in a trial conducted on the Maule Creek Mine site in NSW.

- The soil lab recommended 28 ton of Gypsum and 2.8 ton of magnesium oxide to adjust p/H (9.7) and balance the calcium magnesium ratios and reduce sodium levels.

- The EnviroStraw program was simple reshape the batter and prepare a suitable seedbed and apply the EnviroMatrix Erosion Control Matrix, Biotic Growth Amendment at a 10 ton to the hectare rate. (More detail is available on request).