On any revegetation project, machinery is required at some point to complete the job. EnviroStraw’s range of revegetation products and solutions are designed to significantly reduce both machinery hours and the amount of water used in the revegetation process.

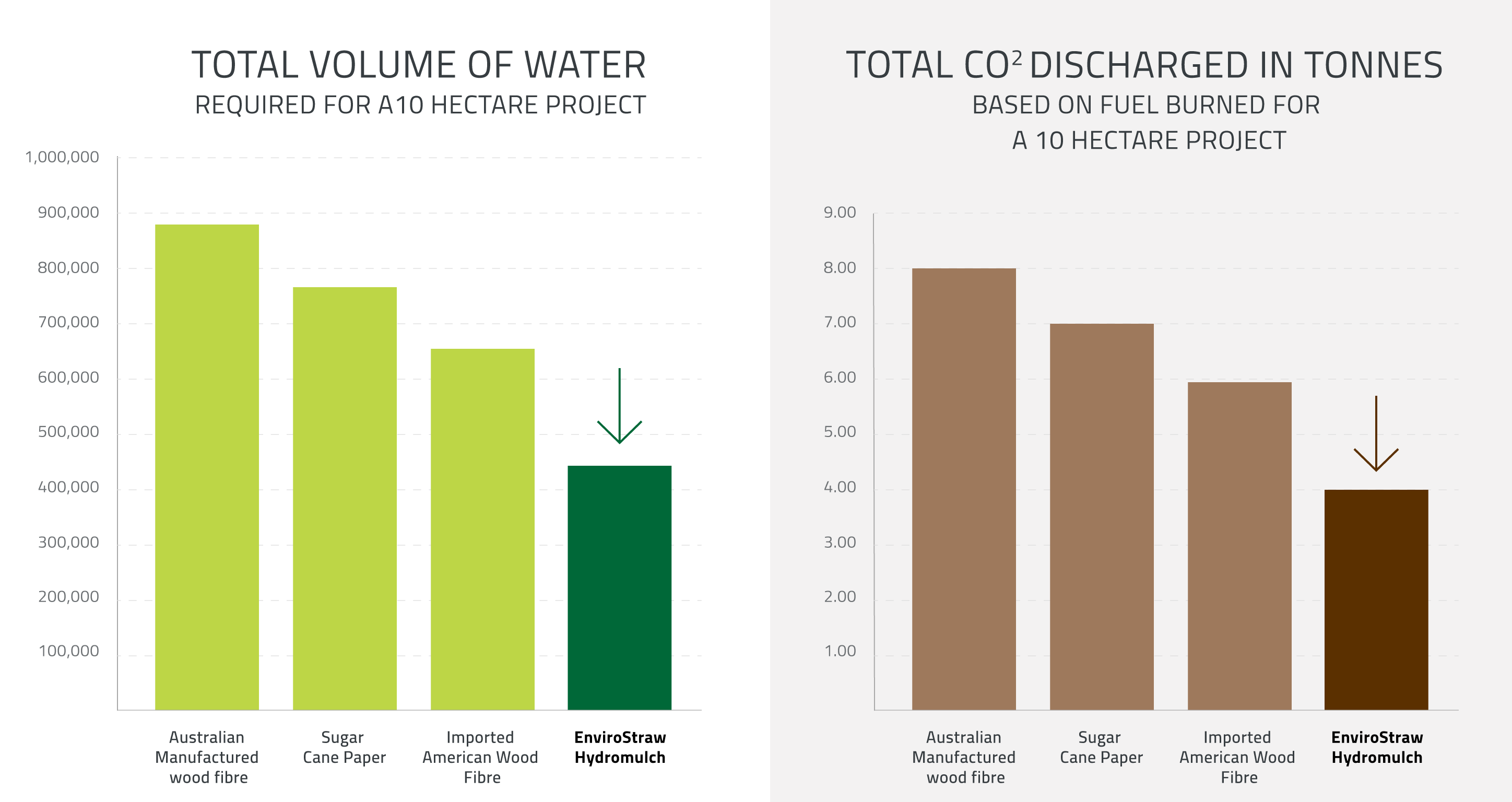

It all comes down to our superior mix ratio. EnviroStraw’s Australian-designed and manufactured range of hydromulch products boasts a mix ratio that’s up to 50 per cent higher than other hydromulch products on the market. This increased mix ratio does two things:

- It reduces the machinery operating hours on site to minimise carbon emissions

- It reduces the volume of water required because the application contractor is able to spray more soil surface area with every tank.

Carbon emissions and water use can be reduced even further by adopting EnviroStraw’s advanced revegetation program, BioGrowth™.

How does this work? Put simply, the BioGrowth™ program is not as reliant on large amounts of soil conditioner.

Unlike many other revegetation methods, BioGrowth™ does not require high volumes of soil conditioners like lime, gypsum, dolomite and compost. Instead, it uses the power of microbes – beneficial microorganisms that recondition soils faster, with less inputs. This in turn provides significant on-site reductions in CO2 emissions.

We worked on a 15 hectare project recently where conventional soil science would have specified five tonnes of lime, five tonnes of gypsum and five tonnes of dolomite per hectare. The BioGrowth™ program, in comparison, required less than one tonne of our Calcium Plus product and less than one tonne of our Carbon Plus product, applied in tandem via a hydromulch truck.

Adopting the BioGrowth™ program significantly reduced the movement of machinery on site due to the fact that only a water truck, hydromulching truck and forklift were needed. In comparison, a traditional program would have required multiple deliveries of 150 tonnes of bulk materials. At least one long-haul truck, an excavator, a tip truck or two and a loader would have been required to manage these bulk materials. Then you have to factor in the time required to spread 150 tonnes of soil conditioner. This all adds up to a lot of machinery hours and associated CO2 emissions.

Revegetating your roadworks, construction or mining site with the EnviroStraw BioGrowth™ program means you can load and spread the comparatively small amount of soil conditioner in less time using fewer machines.